In high-risk work environments where working at heights is commonplace, ensuring the safety of workers is paramount. One of the critical safety gears designed for this purpose is the full-body harness. This article delves into what a full-body harness is, why it’s essential, and how to ensure its effective use in preventing fall-related injuries.

Understanding Full-Body Harnesses

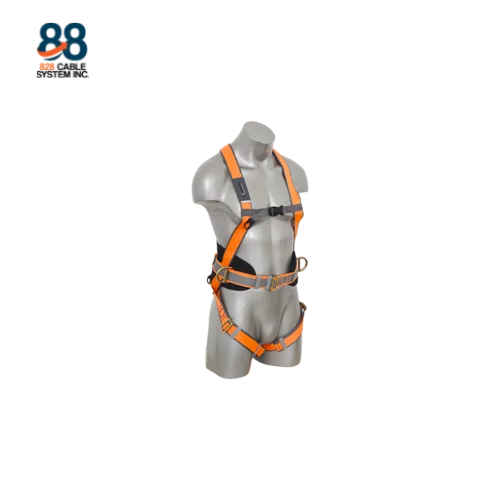

A full-body harness is a crucial safety device designed to protect workers in the event of a fall from heights. It consists of straps that securely wrap around the user’s torso, shoulders, and legs, distributing the impact forces of a fall across a wide area of the body. This design helps to minimize the risk of serious injury by preventing suspension trauma and reducing the impact on vital organs.

Industries such as construction, telecommunications, and utilities commonly require workers to use full-body harnesses when working at elevated heights. These harnesses come in various types, each suited for specific work environments and tasks.

Importance of Fall Protection

Fall protection is vital in industries where workers are exposed to fall hazards. Statistics reveal that falls are among the leading causes of serious workplace injuries and fatalities. Before the introduction of full-body harnesses, older devices like body belts were used for fall protection. However, these were found to contribute to internal injuries and were consequently banned in 1998.

Unlike body belts, which could allow a worker to slip out during a fall, full-body harnesses securely hold the worker in place, significantly reducing the risk of injury or death.

Key Safety Guidelines

When using full-body harnesses, adherence to safety guidelines and regulations is crucial. According to occupational safety standards, if a worker is operating at heights exceeding six feet, a fall arrest system must be in place. This system should limit free fall to no more than six feet and provide a deceleration distance of at least 3.5 feet. Additionally, the maximum arresting force on the body in the event of a fall should not exceed 1,800 pounds.

It’s essential for employers and workers to understand these specifications and ensure that the harnesses used meet these safety requirements. Proper training on the correct use and inspection of harnesses is also necessary to prevent accidents.

Proper Inspection and Maintenance

Regular inspection and maintenance of full-body harnesses are critical to their effectiveness and the safety of workers. Harnesses should be inspected before each use and regularly by a competent person for signs of wear, damage, or deterioration. Common inspection points include straps, buckles, D-rings, and stitching.

If any damage or wear is detected, the harness should be taken out of service immediately and replaced or repaired by a qualified professional. Harnesses that have been involved in arresting a fall must undergo a thorough inspection and certification before being used again.

Training and Compliance

Proper training in the use of full-body harnesses is essential for all workers who may be exposed to fall hazards. Training should cover the correct method of donning and adjusting the harness, as well as how to inspect it for defects. Workers should also receive instruction on the specific fall protection systems and equipment used in their workplace.

Compliance with safety standards and regulations is not only a legal requirement but also ensures the safety and well-being of workers. Employers should stay updated with the latest safety guidelines and provide ongoing training and support to their employees.

Takeaway

Full-body harnesses play a crucial role in protecting workers from fall hazards in high-risk industries. By understanding their purpose, adhering to safety guidelines, and ensuring proper inspection and maintenance, employers can significantly reduce the risk of fall-related injuries and fatalities. Prioritizing worker safety through comprehensive training and compliance with safety regulations is essential for creating a safe and productive work environment.